SSbD4CheM’s automotive case study presented at PARC meeting in Oct.2025

In October 2025 (concretelly on Oct. 15th), Ivana Burzic, from Wood K plus, presented SSbD4CheM’s automotive case study at a dedicated meeting on the PARC project (European Partnership for the Assessment of Risks from Chemicals).

In her presentation, Ivana highlighted the safety (emissions) and sustainability (recycled materials, cellulosic fillers) goals of this case study on renewable based composites (WPC) with optimized TVOC emissions and odor for automotive car interior trims, as well as how the project is implementing all 5 steps of the SSbD framework. The presentation also covered different tests performed like weathering and TVOC emissions, before and after weathering tests, to ensure a safer production and application of the composites developed within the project, covering different cellulosic materials. The presentation also included LCA results.

The online meeting gathered PARC partners and European Commission Joint Research Centre (JRC) representatives to exchange experiences and contribute to building the EU SSbD toolbox. This collaborative effort supports a harmonised European approach to safer and more sustainable chemical assessments, enhancing environmental and health protection.

Demonstrating cross-project commitment to SSbD principles, Ivana also presented BIO-SUSHY’s food tray packaging as a case study, highlighting the PFAS-free, bio-based coatings that embody safety and sustainability principles from the very beginning of development.

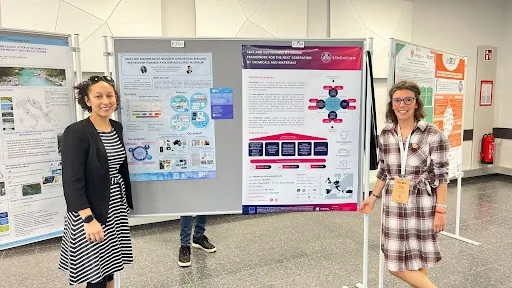

This engagement underscores SSbD4CheM’s active participation in the European SSbD community and reinforces its position as a reference point for sustainable materials innovation.

The presentation is publicly available under DOI: 10.5281/zenodo.17403579 (Creative Commons Attribution 4.0 International license).